Absolute Marks 30 Years of Machining Evolution

Examples of process and setup consolidation include demos on twin-spindle five-axis machines and multi-slide CNC screw machines.

Matt Danford

Former Senior Editor, Modern Machine Shop

Importer and distributor Absolute Machine Tools celebrates its 30th anniversary at this year’s IMTS, and the company’s booth is awash with examples of how much machining has changed in the past three decades.

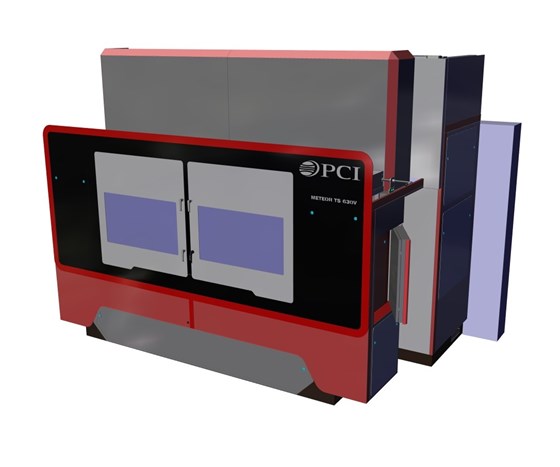

Trade show exhibits have changed, too. At the center of the booth is a massive screen, sized and shaped to match the front of a Meteor-brand five-axis machine from PCI, a French company owned by Absolute partner Tongtai (formerly Hitachi Seiki). On-screen “doors” open to reveal two horizontally-mounted spindles processing different parts independently.

The Meteor demo isn’t the only demonstration to showcase the trend toward consolidating operations onto fewer platforms. Others show how multi-slide CNC screw machines can offer a cost-effective alternative to multi-spindle machines. In one demo, a fitting typically made on a multi-spindle is instead produced on a Lico multi-slide CNC screw machine. With capability to cut with three tools at once, this machine reduced costs while maintaining the same cycle time. On another Lico machine, drills and reamers from Dayton, Ohio-based Greene Tool create accurate square corners in a simultaneous drilling and pinch-turning process. With three tools in the cut at the same time (two OD tools and one ID tool), this process ensures efficiency and prolongs tool life in these difficult applications.

Another demonstration involves AccuteX’s AL-600SA wire EDM. At the center of this profile-cutting process is not a paper blueprint, but a 3D model representing the ideal geometry of a solid carbide cutting tool inserted with polycrystalline diamond (PCD). First, the operator uses a macro in Esprit CAM software to program an onboard Marposs probe to take data from select points on the part. Comparing the real-world part to the virtual ideal reveals the inherent surface inaccuracies that result from the PCD brazing process. From there, the conversational macro uses the probe data to guide the operator through wire-path adjustments that ensure the real-world cutter matches its digital twin.

In yet another demo, a Tongtai SH-4000P horizontal machining center will cut 6-inch-wide, 10-inch-high 30th anniversary logos that will decorate the company’s four North American Technical Centers. Fittingly for an era when importing and distributing machines requires automation expertise, the application utilizes a pallet changer and dual tombstones to rotate the aluminum blocks to a 45-degree angle.