Electric Vehicles Spark Bright Ideas

Ford alone expects to have production capacity for 600,000 electric vehicles by late 2023, and more than 2 million by the end of 2026. The effects on manufacturing are BIG.

Gary S. Vasilash

Transportation Editor, Gardner Business Media

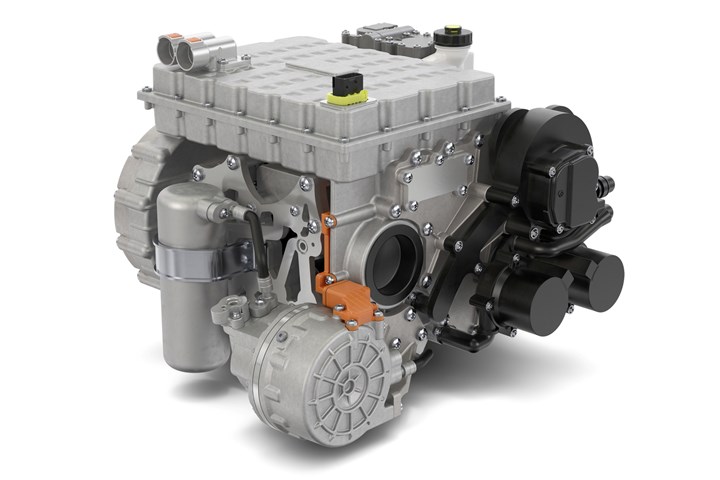

Automotive supplier Schaeffler is using existing manufacturing equipment as well as acquiring new assets in order to produce products for electrified vehicles, including this electric axle, which combines the electric motor, power electronics, transmission and thermal management system into one package. Photo Credit: Schaeffler

One of the things about electric vehicles (EVs) is that they are in many ways like non-electric vehicles (typically referred to as “ICEs,” as they are powered by internal combustion engines).

Or, as Sandy Munro, CEO of design, engineering and manufacturing consultancy Munro & Associates puts it: “As far as ICE build vs EV build: it is about 65% the same. Bodies are bodies, seats are seats, IP’s are IP’s.”

He adds: “Everything changes when you address powertrain, electronics and customer delights.”

And change is upon us, as Munro says that while the market share in the U.S. for EVs will be about 5% in 2022, he expects that to double in 2023 to 10%, 20% in 2025, and so on.

Manufacturing Effects

Let’s put customer delights aside and look at the powertrain and the electronics: what are the effects on manufacturing?

So we asked Chris Shamie, vice president—Hybrid Drives, eAxles and the Product Management Office Schaeffler, a global automotive supplier of engine, transmissions, chassis, and hybrid and electrified drive systems. How does a company that was established in 1883 with a steel ball grinding mill adjust to changing demands?

To put it into context we asked about the development of an electric axle that the company announced in June.

Shamie explains, “A turn-key electrical axle is made of three required building blocks: a transmission, an electric motor, and a power inverter. The mechanical components for the transmission tend to be cold-formed components, which Schaeffler has made for the last 75 years.”

So that process remains largely the same.

The FANUC M-1000iA robot, seen here handling a 1,000 kg EV battery pack in Booth 338919 at IMTS 2022

Making Motors

Shamie continues, “While electric motors has ‘electric’ right in the name, they are still largely a mechanical sub-system made up of stampings, plastic moldings, and copper windings. We at Schaeffler consider stamping to be one of our core competencies, so there is not too much of a transformation there for us. Our division Elmotech-Statomat has wound motors for decades, so we are on a good path there as well.”

Again, fairly standard.

Inverters Are Different

However, the inverters are somewhat different: “To deliver power inverters for our 3-in-1 systems, Schaeffler works with many supplier-partners to utilize existing manufacturing footprints to reduce production lead-times.”

Here it is leveraging suppliers.

Shamie adds that eAxles can also use thermal management modules and driveline disconnects, the types of actuators Schaeffler has long been producing.

Changing Needs

But don’t think this is all status quo.

Shamie: “As we move from delivering products for combustion powertrains to electrified powertrains, we see a bit less need for cold-forming tools and a bit more need for things like die-casting tools, injection molding tools, and tooling to support actuators and power electronics.”

The good news for Schaeffler is that it has those capabilities.

Lower Volumes

One interesting aspect of the change in powertrain types is that electric drives require fewer components than combustion engines. So this means suppliers need to focus on cost efficiency in order to maintain margins because of the reduced volumes. Shamie says, “This requires looking at every opportunity, including new and optimized manufacturing techniques.”

Shamie says that while they are using additive in prototypes, “In the future we will very likely see this move into mass production, but for the types of components that we are using for electrified drives, the value equation is not yet on our side.” He adds, “But I am sure it will get there.”

More Stamping

But there are traditional processes that need to undergo change in order to meet the demands of the electrified drives. Like stamping.

Shamie says that one of the ways electric motors can be more efficient is to reduce the thickness of the laminations used. This means that there is a need for more stampings per motor.

He explains, “The challenge really becomes how we move material in the stamping dies. In the old days, you could push 5 mm material through a die pretty easily. But as we approach 200-micron material thickness, we need to make sure that we design our tools and processes in such a way that we are robust to this thinner material.”

The Biggest Challenge

What is the biggest challenge in making the transition from ICEs to EVs to manufacturing?

“The biggest issue we face as an industry is that the electrified drivetrain paradigm has not yet been defined,” Shamie answers.

There are differences in designs, differences in types, differences in power.

So what’s a supplier to do?

The answer to that question may make or break many supplier companies.

Shamie says, “You can choose to just bet on one technology, and if you do that, you severely limit the market that you can service.

“You can be agnostic to the different technologies and support all of them, and this leads to reduced benefit of scale.”

He concludes, “We will see this challenge for at least the next decade until the powertrain paradigm starts to take shape.”

The International Manufacturing Technology Show runs September 12 - 17, 2022 at McCormick Place in Chicago. Register for IMTS today to start planning your show.

.jpg;width=70;height=70;mode=crop)