IMTS Ripe with Mold and Die Technology

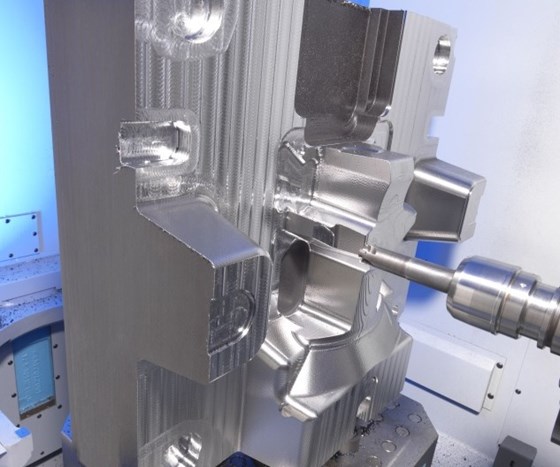

The complexities and tight tolerances of mold work make it a very demanding trade.

The skilled trade of moldmaking is unique in that its challenges differ from those of a typical job shop. For instance, a job shop will generally focus on a singular part or process, which will eventually be married to other components in a product. A moldmaker has to understand the big picture. Moldmakers must consider part design, mold cavity design, material selection, machining, programming, validating, assembly, testing and sampling. Digging a little deeper, the geometry of the molded part can be challenging with tight dimensional tolerances, strict flatness specifications and thin walls; complex mold actions may be required to create some part features; and working with multiple materials, multiple sets of mold cores and multiple sets of cavities is part of the daily workload. On top of all that, cycle times and lead times are often very aggressive.

In a nutshell, the complexities and tight tolerances of mold work make it very demanding. Modern moldmaking is utterly dependent on accurate, repeatable and efficient technologies throughout the design and build stages. All of this requires additional resources, more elaborate planning and closer project management.

Today, there is a trend toward more complex, precise parts and consolidating multiple existing parts into a single part. This means more complex, precise mold designs and machining as well as maintenance and repair processes and strategies. The industry is also continuing to experience the need to automate and digitize production processes. This means that moldmakers must be innovative and invest in the latest equipment to stay ahead of the competition. However, technology is not enough. Mold builders must combine technology with organizational and management systems with cost control and qualified human resources.

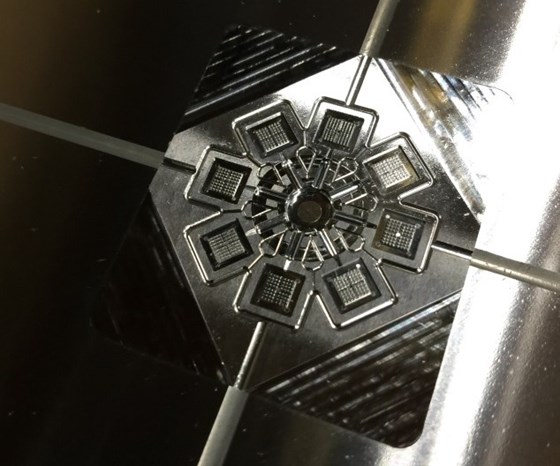

Some more specific challenges voiced by mold builders today include implementing a customer relationship management (CRM) system, integrating simulation with existing CAD/CAM software, deciding between a vision system or a coordinate measuring machine (CMM), employing on-the-machine scanning, monitoring machine performance, increasing precision with the right controls, modifying machine designs, applying waterjet cutting, determining how to use 3D printing, making the move to five-axis machining, producing tool paths to increase efficiency and improve surface finish, using the cloud to improve levels of collaboration, adapting more complex machining strategies, achieving economy in finish milling, utilizing optimized roughing, attaining repeatability of processes and surface quality, reducing or avoiding hand polishing, making investments in hard-milling, expanding the number of vertical or horizontal machining centers, adding CAM software for toolpath optimization, using magnetic workholding for maximum workpiece access and employing deep-hole drilling/milling.

IMTS is a place that offers mold shop owners, engineers, designers, builders, machine operators and toolroom personnel miles of technology, networking and resources to help face these challenges head on and eliminate bottlenecks, increase productivity, reduce downtime and improve quality.

According to the Gardner Intelligence Capital Spending Survey to metalworking shops asking about their intended spending on equipment for the coming year, mold builders who participated indicated vertical machining centers, horizontal machining centers, CAD/CAM software, vision systems and robots as their top five equipment-type purchases planned for 2018.

We see some of this technology here at IMTS as mold manufacturers walk the halls of McCormick Place looking for more powerful design and toolpath software; CAD/CAM systems capable of parametric solid modeling, strong surface generation and feature recognition; scanning and reverse engineering; programming verification; high-performance additive and subtractive machining technologies; multi-axis milling; 3D printing; automated electrical discharge machining (EDM) cells; multitasking machines; and welding systems.